Determining the quality of aluminium oxide layer on aluminium foil

This Collage of knowledge is about the design and devlopment of an automated measurement system that can determine the quality of aluminium oxide layer on aluminium foil. It is based on the knowledge of an employee, who is doing the quality test manually using an analog X-t recorder.

Process analysis

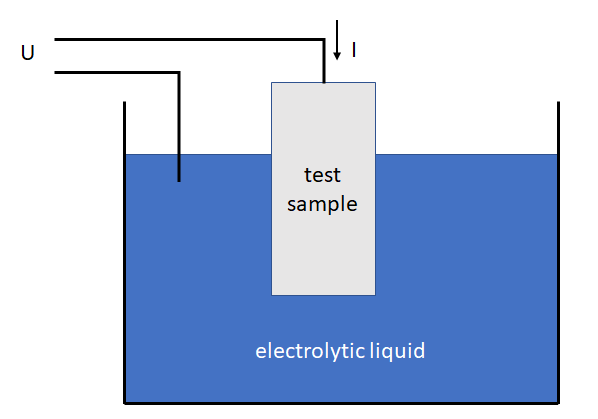

Aluminium foil is a base material for the manufacturing of electrolytic capacitors. This aluminium foil has to undergo some processes before it can be used in the electrolytic capacitor. The forming of aluminium oxide is one of these processes.- Aluminium foil on a roll will be etched by an electrochemical process to increase the surface area on the aluminium foil.

- Etched aluminium foil on a roll will get a thin layer of aluminium oxide via another electrochemical process.

- Check quality of aluminium oxide layer on aluminium foil.

Knowledge identification

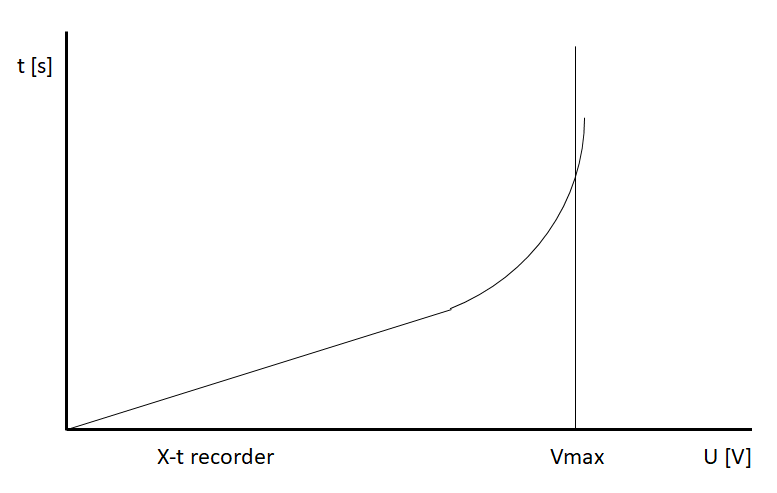

Based on the process analysis it is decided to focus on the quality check of aluminium oxide layer on aluminium foil. To determine the quality of the aluminium oxide layer, an employee performs 2 different tests. For each test an aluminium foil sample will be used, both are of the same aluminium foil roll created during the aluminum foil production.

The 2 graphs will be compared and interpreted by the employee to determine the quality of the aluminium oxide layer on the aluminium foil roll.

Knowledge conversion

In the step Knowledge Identification, it is decided to put the focus on the knowledge of the employee who performs the quality check of the aluminium oxide layer on the aluminium foil roll. The manufacturer of the aluminium foil, that is to be used for electrolytic capacitors, has decided to design and develop an automated measuring system that can do the quality test.The following knowledge conversion steps have been executed to design and develop this automated measuring system.

Externalization: from tacit to explicit knowledge conversion

The purpose of this step is to get a conceptual model which can be discussed further.

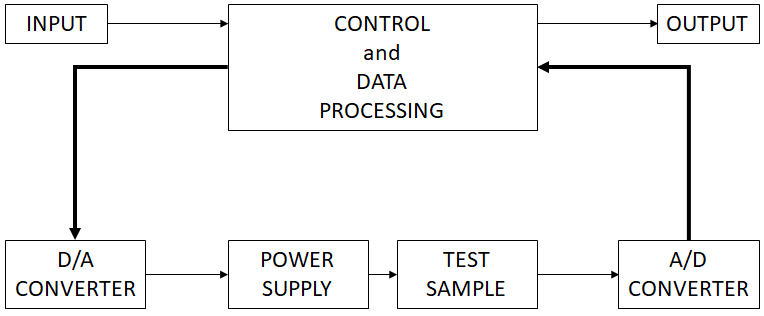

Using systems theory a system model has been created for the development of an

automated system that can determine the quality of aluminium oxide layer on aluminium foil.

Explanation of the model:

- input, via thumb wheel switches data about the test can be entered

- output, via a numeric display and a led the test results will be displayed

- Control and Data Processing unit will control the D/A converter that will control output current of the power supply

- the test sample in electrlytic liquid will create graph voltage data as a reaction on the current applied by the power supply

- the A/D converter will convert the voltage data to digital data and send it to Control and Data Processing unit

- Control and Data Processing unit contains test parameter data and controls the test. It will also record and save the graph data by sampling the data every second during the execution of the test. At the end of the test the data will be processed to determine and present the test results.

Combination: from explicit to explicit knowledge conversion

In this step the automated measuring system will be designed and developed based on the conceptual model and

using knowledge about:

- electrochemical process of etching and growing a thin layer of aluminium oxide on aluminium foil

- computer system development using a microcomputer and analog and digital components

- software development to create the assembly code for the microcomputer that will control the automated measuring system

- technical documentation about analog and digital components and microcomputer

- handbook: Designing with TTL Integrated Circuits, Texas Instruments Inc. 1971

- Datasheet of 8748 micrcomputer: MCS-48 User's manual, Intel 1980

- Several other datasheets of components used

- skills acquired during education BSc. Electrical Engineering

Internalization: explicit to tacit knowledge conversion

In this step the explicit knowledge about the developed automated measuring system is to be transferred to other people,

so they can internalize this knowledge (which becomes tacit knowledge).

For this purpose two documents have been created:

- Handbook that describes the design of the automated measuring system

- Handbook that describes what and how the automated measuring system can be changed